ITEG Software

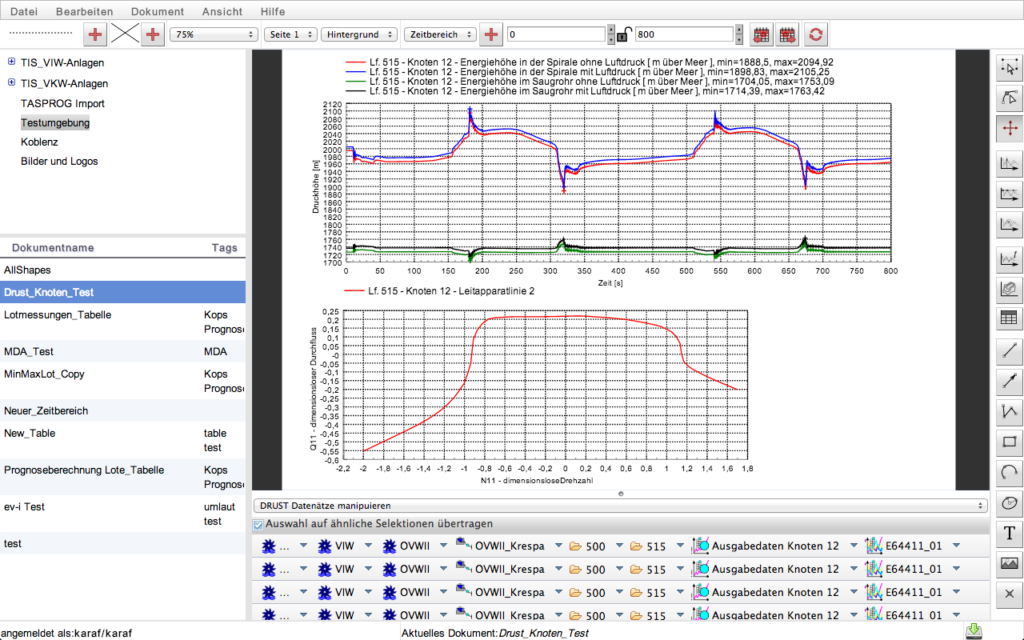

TISGraph allows to visualize time-series data from diverse sources. TISGraph features an extensive toolset for quick and precise layouting of large amounts of data. Whether you want to informally visualize your data or need to compile reports for the authorities, TISGraph lets you simply do it.

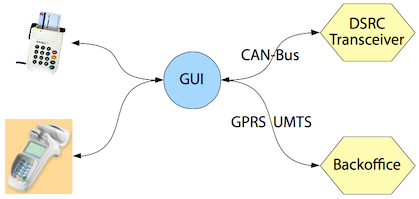

ITEG GmbH is developing MDA (Mobile Data Aquisition), a software solution for the aquistion and management of measurement data with mobile devices. MDA currently focusses on reading data from stationary sensors in the area of water power plants and hydrology.

MDA’s components are designed for ease of operation of the mobile devices and transparent data processing.

Mesurement data are entered Offline using mobile devices with “MDA-Client for Android”, independent from any data connectivity.

Later on the data of a measurement round can be transmitted directly from the mobile device to the server in one short operation. Any available data connection can be used: WiFi, cellular radio, ethernet. No PC is required, no cable connection with USB or RS232, no proprietary PC software.

Central storage and processing of all collected measurement data is performed by a modular server software which is written in Java and can be run on any Linux or Windows system. The server software provides a web interface compatible with any modern browser with support for JavaScript.

Server users can be authenticated against your organization’s Active Directory Server and other authentication backends.

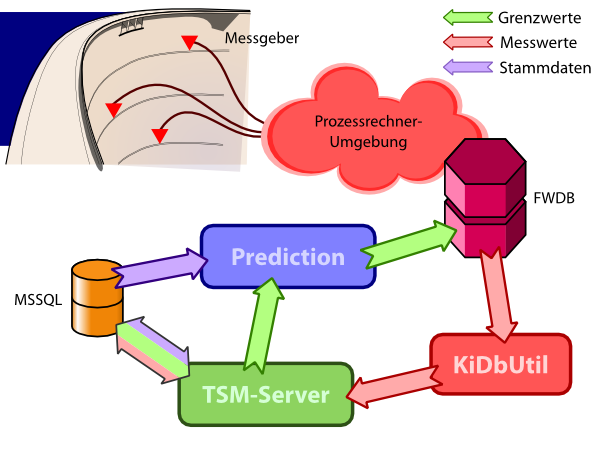

The modular architcture allows as to adapt the MDA-Server to Your needs or interconnect it with other systems.

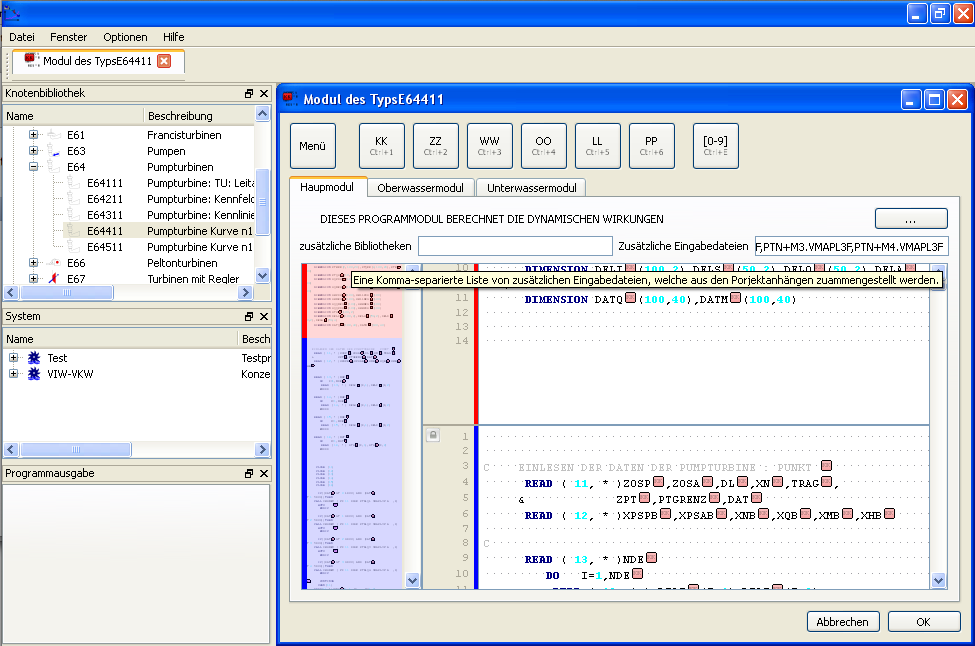

Apart from our own software products we develop individual software according to customer requirements, mostly for infrastructure operators.

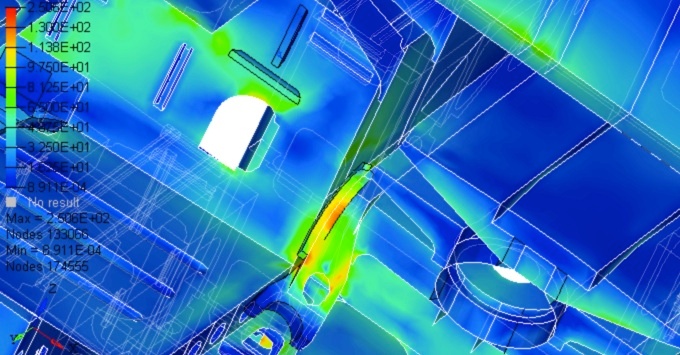

Our software supports security-relevant business-critical applications for several countries’ electronic toll collection system, allow quality management for planning big infrastructure construction projects, and several solutions for operators of dams for power production.

The focus is on:

- Scalability

- Durability

- Security

- Possibilty to monitor services

Feel free to contact us.